Metal machining is crucial in the construction industry, providing the precision needed for creating essential elements like beams, bolts, and intricate parts. Nearly every aspect of a construction project relies on these precisely machined metals to ensure structural integrity and stability.

The beauty of metal machining lies in its versatility and adaptability, enabling the custom fabrication of parts for specific projects and the mass production of standardized components. This precision ensures that every part fits perfectly in structures like skyscrapers and bridges, guaranteeing strength, stability, and overall reliability.

Overview of Metal Machining

Metal machining plays a critical role in shaping and customizing metal components for construction projects. Key techniques and types of machinery are crucial for achieving precision and efficiency.

Definition and Techniques

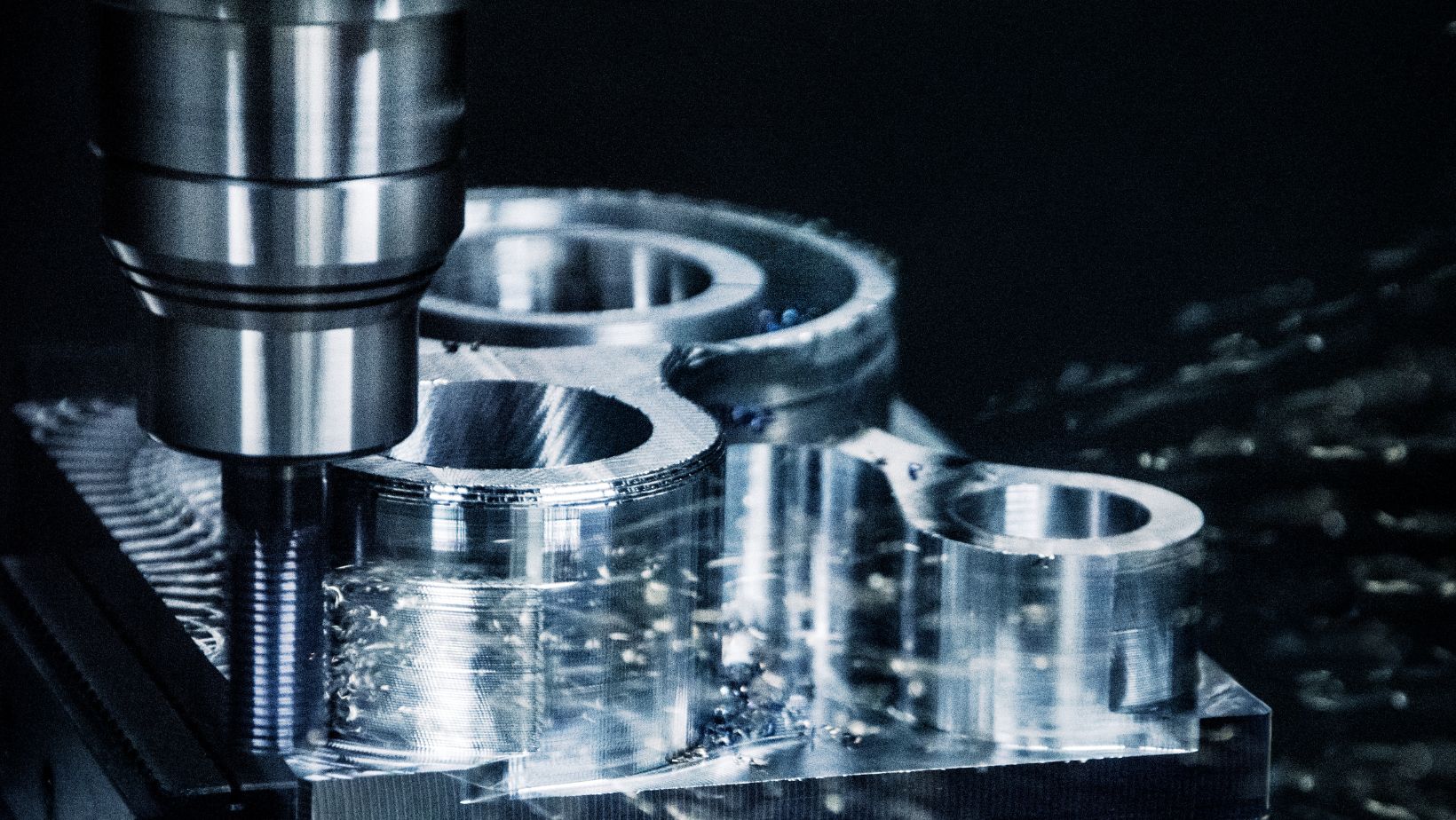

Metal machining involves the process of removing material from a workpiece to achieve a desired shape and size. Key techniques include turning, milling, drilling, and grinding. Each method serves a unique purpose; for example, milling is used for creating complex shapes and holes, while drilling precisely creates round holes.

Turning uses a rotating workpiece and cutting tool to shape materials. Grinding, on the other hand, involves using an abrasive wheel to smooth surfaces. These techniques ensure that parts meet strict design specifications and function correctly in their applications.

Types of Machinery

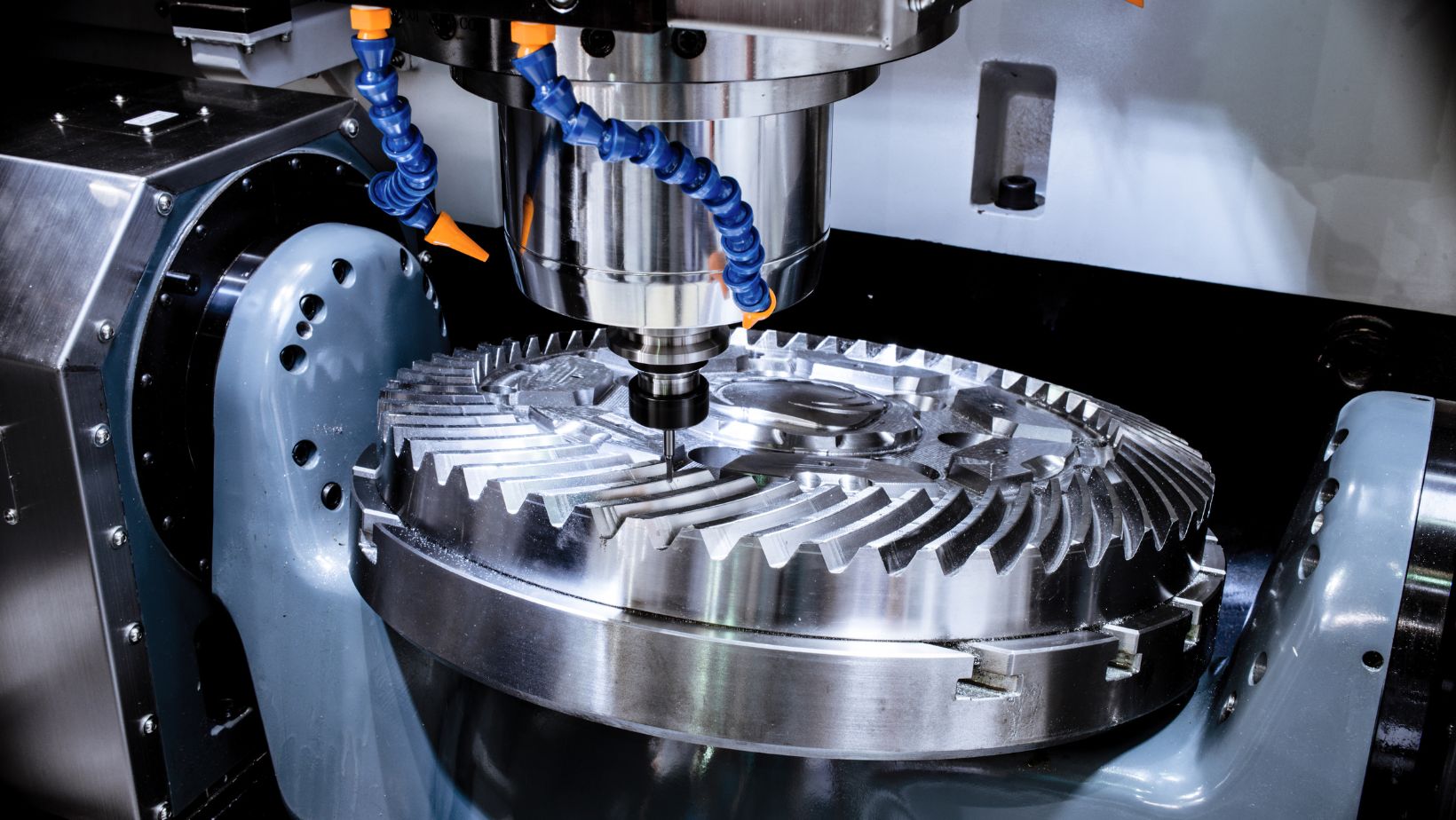

Various machines are employed in metal machining, each suited for specific tasks. Lathes are essential for turning operations, enabling you to create cylindrical parts with precision. Milling machines, capable of vertical and horizontal movements, are versatile for cutting and shaping materials.

When it comes to boring operations, horizontal boring mills are invaluable. These machines, like the Horizontal HB Series, provide high accuracy in enlarging holes. Drill presses are used for vertical drilling applications while grinding machines are crucial for finishing surfaces to high standards.

In summary, metal machining is indispensable in construction. The right combination of techniques and machinery can ensure the precision and quality necessary for building resilient structures.

Machining in Construction Projects

Machining plays a critical role in various aspects of construction projects. It’s essential for creating structural components, mechanical systems, and custom-made parts that are tailored to specific needs.

Structural Applications

In construction, machining ensures the precision and durability of structural elements. Metal frames, beams, and columns are often machined to exact specifications, providing the backbone for buildings and bridges. Accurate machining allows for the creation of parts that fit together seamlessly, enhancing the structural integrity of the entire project.

Precision is key here. A single miscalculation can lead to weaknesses. By utilizing advanced CNC (Computer Numerical Control) techniques, you can achieve the exact dimensions and tolerances required. This leads to safer and more reliable structures that can withstand various stresses and strains.

Mechanical Systems

Mechanized systems in construction, such as elevators, HVAC systems, and water pumps, rely on machined parts. These components need to interact smoothly and efficiently. Machining ensures that gears, shafts, and other mechanical parts meet the rigorous demands of daily operation.

When metal parts are machined precisely, they function better and last longer. This reliability is crucial for maintaining the ongoing functionality of a building’s mechanical systems. The result is fewer breakdowns and less maintenance over time, which is a significant cost-saver.

Custom Components

Sometimes off-the-shelf parts don’t cut it. Custom machining comes into play to create unique components tailored to specific project needs. Whether it’s a unique architectural feature or a bespoke mechanical part, custom machining provides the flexibility you need.

Customization allows you to achieve design goals that standard parts can’t offer. Using 3D modeling software and CNC machining, you can bring complex designs to life. This level of customization not only meets unique aesthetic or functional requirements but also enhances the innovativeness of the construction project.

Challenges and Solutions

Metal machining in construction projects presents several unique challenges. From ensuring high standards in quality control to managing costs effectively, you must navigate various obstacles to achieve successful outcomes.

Quality Control

Maintaining quality control is critical. You need to ensure that machined metal parts meet precise specifications to avoid structural failures.

Regular inspections and using advanced technologies like CNC machines and 3D scanning can help. Implementing rigorous testing protocols and collaborating closely with suppliers ensures that the materials used are of the highest standard.

Cost Management

Controlling costs in metal machining can be difficult due to the high price of raw materials and machinery.

Strategies like bulk purchasing and negotiating long-term contracts with suppliers can help reduce expenses. It’s also beneficial to invest in efficient machinery that minimizes waste and energy consumption while maximizing productivity.

Supply Chain Logistics

Supply chain logistics can pose significant challenges, especially when dealing with global suppliers.

Timely delivery of materials and parts is crucial. You should work with reliable logistics providers and consider maintaining a buffer stock. Transparent communication with all stakeholders helps in planning and mitigating delays that can disrupt project timelines.

Workforce Training

A well-trained workforce is essential for successful metal machining operations.

Continuous training ensures that workers are adept at using advanced machinery and adhering to safety protocols. Partnering with technical schools and offering apprenticeships can help build a skilled team. Regular workshops and certification programs keep your workforce updated with the latest industry standards and technologies.

Sustainability and Advancements

Metal machining in construction is rapidly evolving, focusing on reducing environmental impact and incorporating cutting-edge technology to enhance efficiency.

Eco-Friendly Practices

Eco-friendly practices in metal machining are becoming essential to construction. Recycling metal waste is a major step toward sustainability. Scrap metal from projects is collected and reused, cutting down on the need to mine new materials. Additionally, using energy-efficient machinery reduces power consumption, further minimizing the carbon footprint.

Efforts to reduce harmful emissions from machines involve upgrading older equipment with modern, cleaner technologies. Water use in cooling processes is now more controlled, often involving recycling systems to conserve resources.

Technological Innovations

Innovation in metal machining has dramatically transformed construction processes. CNC machines allow for increased precision and reduced waste, benefiting both the environment and project budgets. Automation has streamlined manufacturing, making production faster and more consistent.

Advancements in tools and materials have also played a crucial role. Durable, high-performance cutting tools extend machine life and improve efficiency. In addition, digital twins provide detailed simulations that help detect issues before they occur, saving time and materials.

Conclusion

Metal machining is crucial for the construction industry, providing precision for creating essential elements like beams, bolts, and intricate parts, ensuring structural integrity and stability for projects such as skyscrapers and bridges. Its versatility allows for both custom fabrication and mass production of components, enhancing the strength and reliability of structures. This adaptability ensures efficient, innovative construction processes, making metal machining an indispensable part of building resilient structures.