Lifting heavy objects and machinery is a common task in many industrial workflows, but it’s not always an easy one. The challenges of lifting can range from inadequate equipment to complex environments and tight spaces. As industries continue to evolve and the demand for efficiency increases, finding innovative ways to solve these lifting challenges becomes crucial.

In this blog post, we’ll explore some unconventional yet effective solutions that can help overcome even the most complex lifting obstacles in industrial workflows. From advanced technology to creative problem-solving techniques, we’ll take a closer look at how industries are tackling lifting challenges head-on. Let’s get started.

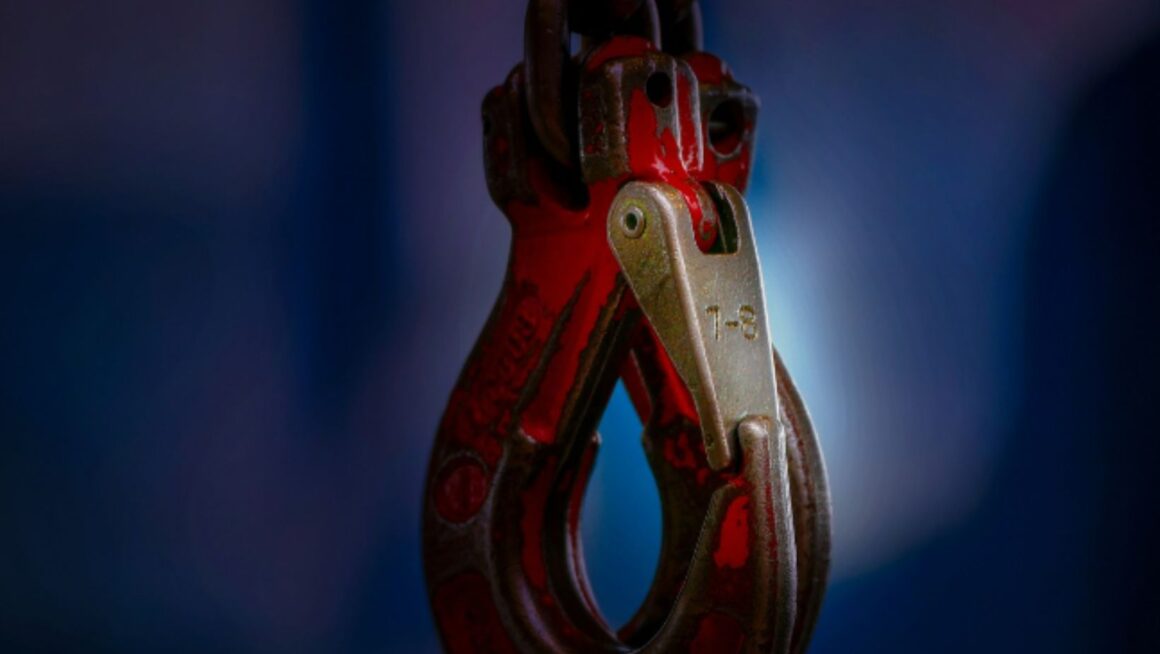

Link Chain Solution

The first innovative solution we’ll explore is the use of link chains for lifting heavy objects. This method involves using a series of interlocking metal links to create a strong and durable chain that can support heavy loads. The benefit of this solution is its versatility, as the length and number of chains used can be adjusted according to the specific weight and size requirements of the object being lifted.

Moreover, link chains are readily available and cost-effective, making them a practical choice for many industrial workflows. For instance, you can find a steel link chain distributor that offers a wide range of options suitable for various lifting applications. With link chains, industries can overcome complex lifting challenges with ease and efficiency.

Robotic Arms

Another cutting-edge solution to complex lifting challenges is the use of robotic arms. These advanced machines are equipped with multiple joints and sensors, allowing them to mimic human movements and lift heavy objects with precision and control. They can also be programmed to navigate through tight spaces or hazardous environments, reducing the risk of injury to human workers.

Robotic arms offer several advantages over traditional lifting methods, including increased speed, accuracy, and efficiency. They also have the potential to operate autonomously, freeing up human workers for other tasks. With the continuous development and integration of artificial intelligence, robotic arms are becoming an increasingly popular choice for solving complex lifting challenges in industrial workflows.

Magnetic Lifters

Magnetic lifters are another innovative solution that is gaining popularity in many industries. These devices use strong magnetic fields to lift and move heavy objects without the need for chains or slings. This makes them a suitable option for lifting delicate or irregularly shaped objects, as there is less risk of damage.

One major advantage of magnetic lifters is their portability, allowing them to be easily transported between different workstations. They also offer a high level of control and precision when lifting, contributing to increased safety and efficiency in industrial workflows. With their ability to adapt to various lifting needs, magnetic lifters present a versatile solution for addressing complex lifting challenges.

Modular Lifting Systems

Modular lifting systems are another increasingly popular solution for handling complex lifting challenges in industrial workflows. These systems consist of interchangeable parts that can be assembled to create custom solutions for different lifting tasks. They offer flexibility and versatility, allowing industries to adapt the system according to changing needs and requirements.

Moreover, modular lifting systems can be easily integrated with existing equipment or machinery, minimizing downtime and maximizing efficiency. The use of standardized components also makes maintenance and repair more manageable, reducing costs in the long run. With their customizable and versatile nature, modular lifting systems are a reliable solution for tackling complex lifting challenges in industrial workflows.

Air Casters

Air casters, also known as air bearings, have been used in industrial applications for many years. However, they continue to evolve and offer innovative solutions to complex lifting challenges. These devices use compressed air to create a thin film of air between the object being lifted and the surface below, reducing friction and making it easier to move heavy objects.

One significant benefit of air casters is their ability to lift extremely heavy loads with minimal effort. This not only reduces the physical strain on employees but also allows for faster and more efficient operations. Additionally, air casters can be used in various environments, including clean rooms and hazardous areas, making them a versatile solution for addressing complex lifting challenges.

Virtual Reality Training

Virtual reality (VR) training is not only a helpful tool for learning new skills but also an innovative solution for tackling complex lifting challenges. This technology allows workers to simulate various scenarios and practice lifting tasks without being physically present in the workplace. By immersing themselves in a virtual environment, workers can develop their skills and techniques while minimizing the risk of injury or errors.

Moreover, VR training can be customized to replicate specific industrial workflows, giving workers a more realistic experience. It also offers real-time feedback and performance tracking, allowing for continuous improvement and risk assessment. With virtual reality training, industries can ensure their workers are well-prepared to handle any complex lifting challenges that may arise.

Industries are constantly facing complex lifting challenges in their workflows. To address these obstacles and maintain efficiency, innovative solutions are necessary. From link chains to virtual reality training, the options discussed above offer various benefits such as versatility, precision, and safety. Industries should continually explore new technologies and problem-solving techniques to adapt to the ever-changing demands of their workflows. By doing so, they can find efficient and effective ways to lift heavy objects and machinery while minimizing risks for workers.