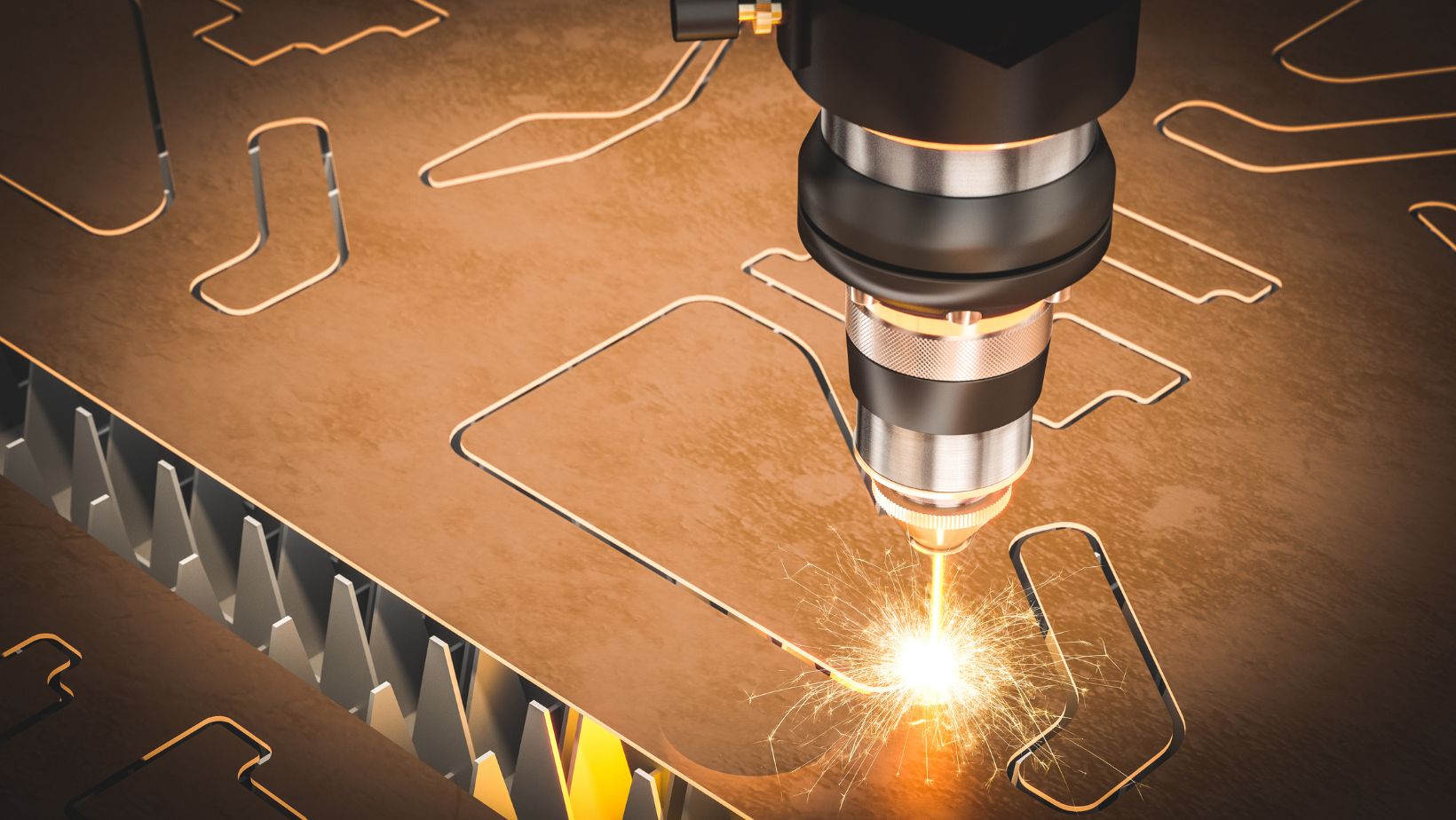

Stainless Steel CNC Machining in Modern Manufacturing. Advances in technology have helped us patent thousands of new stainless steel machines. The accuracy and uniformity of CNC machining enable manufacturers to meet strict requirements in a broad range of industries. Harnessing the latest in technology and industrial experience, firms like Rapid Axis are prime examples of the way that stainless steel CNC machining raises the bar for production with resource optimization, waste reduction, and manufacturing timelines that are faster than ever before.

Stainless Steel is still very commonly selected because of its high corrosion resistance, mechanical strength and suitability for many applications. Via the CNC Machining process, stainless steel components can be manufactured with tight tolerance and high precision. This collaboration helps manufacturers develop parts that meet exacting performance and durability demands, cementing stainless steel CNC machining as a mainstay in contemporary manufacturing.

How Stainless Steel Has Positioned Itself As A Strategic Player In Industrial Manufacturing

The naturally occurring mechanisms of stainless Steel, including its resistance to corrosion, structural strength, and long-lasting qualities, allow it to be used within various manufacturing industries. These characteristics enable parts to function correctly in even the harshest environments, including but not limited to chemical plants, aerospace equipment, and medical devices.

With the addition of CNC machining methods, manufacturers can also take full advantage of such beneficial materials. CNC machinists carry out one step in a series of precise instructions to mill, turn, and drill stainless Steel into a specific shape. This automated methodology prevents human error, guarantees that the design parameters are met reproducibly and allows for scaling the production batches while maintaining quality.

Optimizing Production with CNC Machining Detail.

Stainless steel material is turned into steel pieces by CNC machining through a trained expert who mills, turns, and drills controlled dimensions to weld and assemble. Once the fashion is programmed, the CNC with the digital code operates, and it can make parts with an accuracy of several thousandths of an inch.

Apart from accuracy, CNC machining can save manufacturing time. With automation, the machines can run around the clock with minimal downtime, quick lead times, and enhanced capacity. These savings reduce material waste and decrease labour costs, improving project economics.

Rapid Axis Moving Stainless Steel CNC Machining Effectiveness

Rapid Axis is a leading innovator in stainless Steel CNC machining, demonstrated by its ability to pair state-of-the-art equipment with experienced staff to deliver the highest quality with the most efficient production processes. This high-quality equipment and intense focus on process optimization ensure that components meet or exceed client expectations time after time.

Rapid Axis allows manufacturers to remain competitive in fast-paced markets due to its emphasis on fast turnarounds and versatile production options. The approach emphasizes the substantial use case for working with CNC machining to custom-fabricate stainless steel components, while ensuring the highest quality requirements.

Industry Uses Leading to Demand for Stainless Steel CNC Machining

Precise stainless steel parts made from CNC machining are critical in the automotive, aerospace, medical technology, and food industries. Every industry requires products that must not only meet strict performance criteria but must also be able to perform under these conditions over extended operating periods.

Automotive manufacturers utilize stainless steel CNC machining of components like exhausts, engine or structural parts, which resist stress, heat, or thermal and mechanical loads. Turbine components and structural assemblies with intricate geometries and tight tolerances need to be machined in aerospace to maintain the safety and performance of a vehicle.

CNC stainless steel components must adhere to rigorous biocompatible and sterilization requirements of tools and implants for medical machining. Food processing lines require parts resistant to corrosion for hygiene equipment and sustainability when frequently cleaned and in contact with different liquids.

QC Improvements Due to CNC Machining

And of course, the natural automation and repeatability provided by CNC machining greatly aid in controlling quality. Through their consistent, program-based procedures, CNC machines remove much of the variation caused by manual production techniques. This consistency guarantees that every component is accurate to the design.

In modern CNC systems, the design of a mechanical part and its manufacturing program is highly automated. These characteristics make it possible to detect deviations or faults earlier than possible, leading to corrections before the production of components further down the production chain. Such proactive quality control helps mitigate scrap rates and ensures the end-user never gets a ‘bad’ part.

Partnerships with CNC machining businesses such as Rapid Axis utilize this technology and the associated quality controls to maintain the precision necessary for quality performance and reliability in finished goods.

Stainless Steel CNC Machining: Cost Efficiency and Optimization

Stainless Steel – despite its premium quality, CNC machining limits the amount of waste and increases manufacturing efficiency. With the precise cutting standard for CNC machining , removing material is carefully planned, minimizing waste and getting the most out of raw stock.

Lean Manufacturing At Its Best Rapid Axis uses a lean manufacturing technique to run CNC machining, reducing machine setup times, tool changes, downtime, and other inefficiencies. These process enhancements also enable faster turnaround and decreased production costs, all for a front price.

This cost-effective but precise balance enables manufacturers to deliver high-quality and affordable stainless steel parts, meeting market needs and maintaining their profit margins.

The Sustainability Benefits of CNC-Machined Stainless Steel Parts

Since the 1970s, ecological implications have been more critical for production decisions. CNC machining is achieved by meeting these requirements by making optimal use of materials and considering the environment. The material used is otherwise a waste product, as we only recycle what is needed. Therefore, the method used in this study leads to reduced environmental burden by recycling stainless steel scrap.

In addition, the recyclability of stainless Steel improves the sustainability of CNC-machined parts. The reclaim and reuse of material is consistent with circular economy tenets, which allows manufacturers to meet their responsible production obligations.

By working with advanced CNC machining services like Rapid Axis, businesses can incorporate sustainability into their supply chain, all while producing high-quality parts.

The Importance of Skilled CNC Operators

Even with the modern CNC machine, experienced machinists are still crucial to successful stainless Steel machining. Machine operators set up equipment, choose tools, and supervise running shifts for smooth production.

A Whakatipu Business Rapid Axis is committed to ongoing training and development of its technicians to maintain currency in CNC and machine technology. This human capability augments automation by allowing complex or bespoke parts to be problem-solved and processes to be tailored quickly.

High-tech CNC machinery and experienced operators afford superior quality and fast delivery.

Trends in Stainless Steel CNC Machining on the Rise

Nowadays, the development of stainless Steel CNC machining is technology-driven. Improvements in machine speed, multi-axis, and integration with software will increase the speed and accuracy of these processes.

CNCs are now also being impacted by artificial intelligence and machine learning, leading to predictive maintenance and adaptive process control. We can expect to see these advancements lower downtime and increase the reliability of the overall manufacturing process.

Material developments, such as advanced stainless steel alloys, continue to push the refinement of machining operations to reflect the changing needs of the industry.

Businesses such as Rapid Axis are in the best position to address these trends and lead in providing excellent and efficient CNC-machined stainless steel components.

How to Choose a Stainless Steel CNC Machined Parts Partner

The right CNC machine shop partner is key to manufacturing success. Some of the critical factors are experience in machining stainless steel, technical capacities, and the provider’s commitment to quality control.

Rapid Axis stands apart with our end-to-end home-to-hard-wall approach to output using top-of-the-line machinery, in-house quality standards, and expedited customer service. They can handle complex projects and tight schedules to deliver accurate, timely parts.

Involving skilled CNC machining facilities reduces risk, shortens production cycles, and improves product performance.

Conclusion

Stainless steel CNC machining is a core driver of manufacturing quality and efficiency. When combined, the durability of stainless Steel’s physical properties and the accuracy and automation of CNC machining work to provide quality and reliable, high-performance products across a variety of industries.

Solution providers like Rapid Axis prove that advanced CNC capabilities and adherence to strict quality control result in their priority selection for the best manufacturing experience. Through heightened cost efficiency, sustainability, and process control, stainless steel CNC machining empowers manufacturers to continue providing for market changes with nimbleness and assurance.

Investing in CNC machining technology and relationships will be the driving force behind manufacturing success both now and in the future.